Automation Reduces Data Analysis Time during Process Qualification in Medical Device Manufacturing

Analyzing data for process qualification is an essential practice of medical device manufacturing. It’s also an exercise in copy, paste and patience.

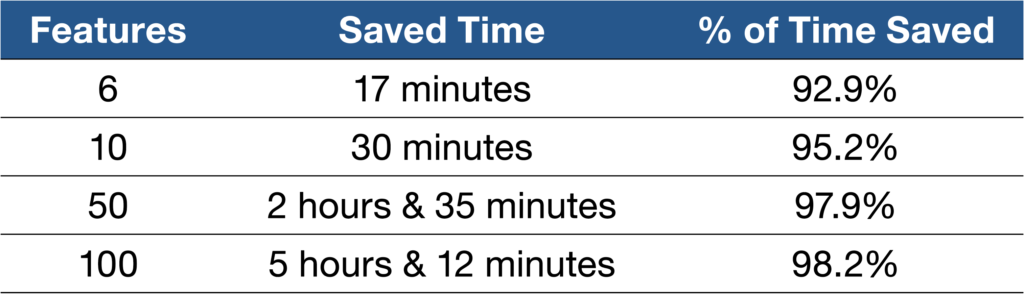

There are a lot of data points to be analyzed during process qualification. Each column of data must be copied from a spreadsheet and pasted into a software program for data analysis. What may be a straightforward process for a part with six features quickly becomes more complex and time consuming as the number of features increases.

Lowell has successfully reduced the time it takes for data analysis by up to 98.2 percent, thanks to a statistical analysis macro that automates this part of process qualification for medical devices.

We recently shared benefits and lessons learned from building our automated program in the Orthopedic Design & Technology article, “Automated Data Analysis: Making the Case.”

Reducing time spent on process qualification is just one benefit of automation

Developing a macro to run data analysis can be an investment in time and resources.

We found that one of the biggest and ongoing benefits of automation was reducing the time spent analyzing data. Three additional benefits include:

- Improved accuracy by reducing the chance of human error when copying and pasting specifications and data

- Increased customer confidence by demonstrating that the manufacturing process meets requirements

- Enhanced reporting by using a standardized format that quickly pulls relevant data together

Building a data analysis script or program requires buy-in from a variety of stakeholders

Automation scripts or macros allow you to analyze a large amount of data at one time, then generate relevant charts or graphs that can be used and shared with customers. Often, these scripts and macros can make a process that previously required hundreds or thousands of clicks into one that’s complete in a few dozen.

Macros or scripts can be created for a variety of statistical analysis programs, with JMP and Minitab commonly used by medical device OEMs and their contract manufacturers.

Lowell built PQ-it, its automated data analysis macro, internally. It was an involved undertaking, and was made possible because of buy-in from leadership and other stakeholders at the company. The result allows us to save hours of analysis time on the most complex devices, while also improving accuracy.

Improving medical device timelines and partnerships through automated data analysis for process qualification

Through process qualification, medical device contract manufacturers confirm their manufacturing process will reliably and repeatedly produce parts that meet requirements and expectations. This is an important step in building OEM confidence.

Companies can see a number of improvements by implementing automated data analysis. As we rolled out this approach internally, additional benefits we’ve seen include:

- Removing the analysis burden from OEMs: Some OEMs are used to suppliers handing over raw data for internal OEM teams to analyze. By analyzing data on the parts we make, we can free up time for OEMs and add value to our partnership.

- Quicker analysis turnaround times: With automation, we’ve been able to shorten analysis turnaround times. In some cases, we recorded, analyzed and presented data to OEM customers on the same day.

- Simpler reporting: The PQ-it macro automatically compiles four common statistical analysis charts into one quad graph, so we can more easily find and report results.

To learn more about the benefits of automated data analysis for process qualification in medical device manufacturing, read our column in ODT or explore our PQ-it macro for Minitab.

13485:2016 Registered

13485:2016 Registered