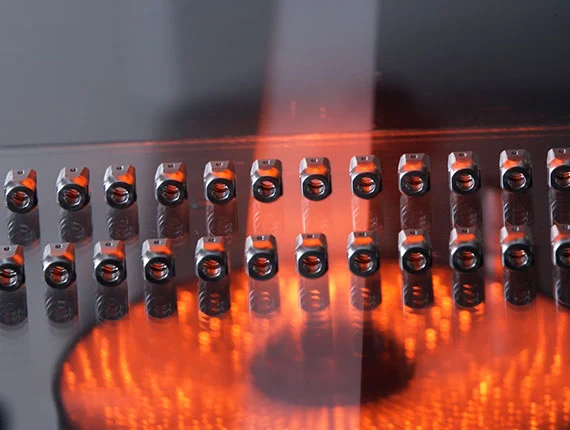

Quality for the most complex geometries

Our customers demand quality in increasingly complex geometries. To achieve these results, our quality assurance efforts combine data-driven manufacturing and validation, advanced technology and staff expertise.

Inspection, validation and data correlation are key pillars of our commitment to quality. Our quality system is certified to ISO 13485:2016, and our team includes many ASQ certified inspectors.

In addition to our on-site inspection lab, we make ongoing investments in technology to assure parts are made to your specifications.

Lowell makes ongoing investments in technology to manufacture and test your finished components and assemblies.

Our proven manufacturing process helps improve time to market through profile tolerancing, GD&T, critical feature confirmation and design intent.

At Lowell, everything starts with our people — experienced, trained, professional, precise.

All of the plates looked awesome! Also all of the specs were right on from what we could inspect here and we had to send out for some dimensions we couldn’t inspect in our lab. So far so good and we couldn’t believe the finish you were able to accomplish – that in itself was very impressive. Thanks for all of the hard work on this project.