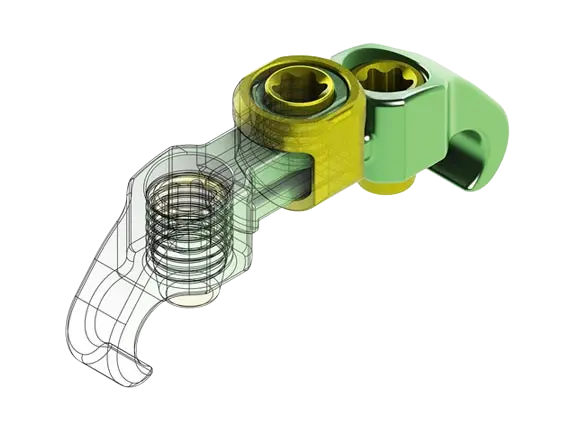

Our journey in MedTech began with a powerful legacy: a manufacturing blueprint forged in the demanding worlds of aerospace and defense. These industries taught us that there is no room for error, that materials must be pushed to their limits, and that timelines are absolute. This foundation of rigorous standards has been our guide for nearly two decades in the spine industry.

We leverage this heritage to work with challenging materials, maintain exceptionally close tolerances, and deliver on tight timelines. It’s more than just a history; it’s our operational DNA, ensuring every component we produce meets the most stringent quality and reliability requirements.

All of the plates looked awesome! Also all of the specs were right on from what we could inspect here and we had to send out for some dimensions we couldn’t inspect in our lab. So far so good and we couldn’t believe the finish you were able to accomplish – that in itself was very impressive. Thanks for all of the hard work on this project.

In a recent collaboration, a client approached us with the challenge of manufacturing complex spinal plates requiring an unprecedented surface finish. Leveraging our aerospace-derived techniques, we delivered a product that not only met all specifications but exceeded their expectations, enabling their surgical teams to achieve optimal outcomes. This project demonstrates our commitment to delivering both aesthetic excellence and functional superiority in every piece we produce.

Contact us today to speak with a member of our team, arrange a facility tour, or request a quote for your project.

Get the information you need from Lowell to move your project ahead or give us important feedback. Fill out the form or contact us at :763-425-3355

13485:2016 Registered

FDA Registered

#2134470

© 2025 Lowell Inc.